时间:2025-04-16 16:15:10

Recently, the Micro Motor Branch of the China Electrical Equipment Industry Association released the economic data of the micro motor industry for last year. Data shows that indicators such as the total industrial output value, sales revenue and total profit of this industry have all maintained a considerable growth. Currently, China has become the world's largest manufacturing base for micro-motors.

A number of domestic enterprises with considerable scale and strength, such as Wolong Holding Group Co., LTD., Zhangqiu Haier Motor Co., LTD., and Zhongshan Dayang Motor Co., LTD., have achieved strong comprehensive strength and good brand recognition by transforming their business mechanisms and innovating management systems. In recent years, many enterprises have invested a large amount of funds in technological transformation, introducing advanced manufacturing and testing equipment from abroad, which has improved the quality and stability of their products. The ability to develop new products has been significantly enhanced, and the capacity for mass production has been formed.

The market size has expanded rapidly

The association learned from an authoritative institution that last year, 772 micro-motor manufacturing enterprises had more than 200,000 employees and an industrial output value of 67.464 billion yuan, an increase of 30.04 year-on-year. The sales revenue was 65.13 billion yuan, increasing by 28.23% year-on-year. The export delivery value was 24.806 billion yuan, increasing by 13.97% year-on-year. The sales rate of industrial products reached 96.54, the output value rate of new products was 10.02, the export delivery value rate was 38.09, the industrial added value rate was 25.07, and the total asset profit rate reached 6.74. Among them, there were 104 loss-making enterprises, accounting for 1.347 percent, with a loss amount of 233 million yuan.

According to the data provided by the General Administration of Customs, the import volume of micro-motors reached 19.87 million units, increasing by 8.96% year-on-year. The total amount reached 864 million US dollars, increasing by 16.27 year-on-year. The export volume reached 177.23 million units, increasing by 25.46% year-on-year. The total amount reached 2.24 billion US dollars, increasing by 41.99 year-on-year.

From the perspective of the distribution location of micro-motor enterprises, enterprises in coastal areas with strong market demand and export advantages have developed particularly rapidly. Most enterprises are concentrated in the Pearl River Delta, the Yangtze River Delta and the Bohai Rim regions.

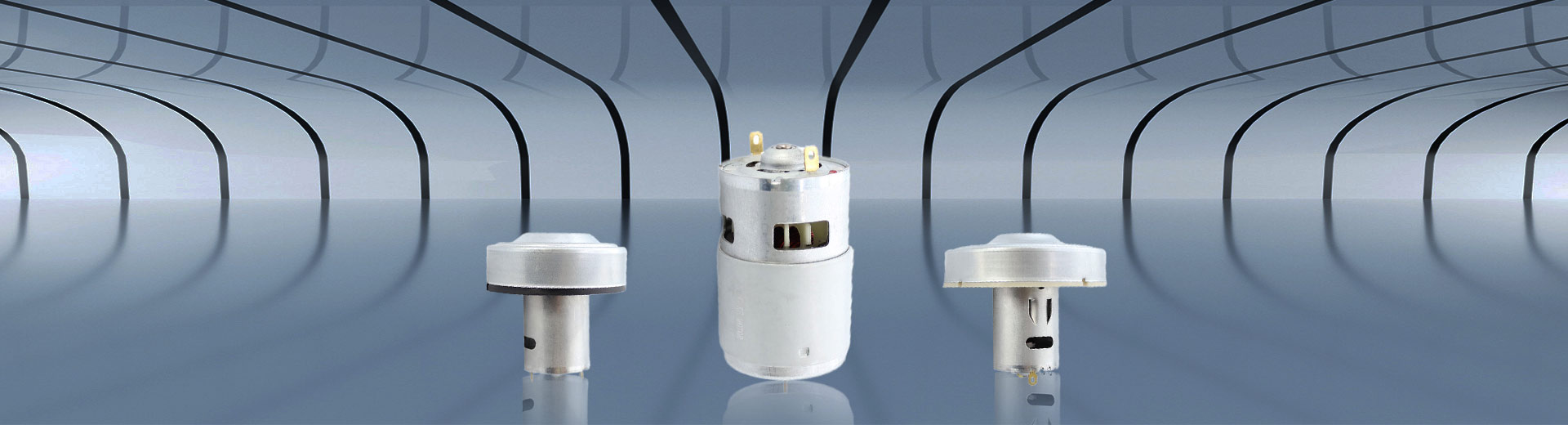

The micro-motor enterprises in the Pearl River Delta region mainly produce various types of micro-motors for information networks, audio-visual fields, home appliances, and industrial fields on a large scale. Their products are mostly brushed DC motors, brushless DC motors, single-phase asynchronous motors, and plastic-encapsulated motors. The total volume of their products accounts for 10% of the global similar products.

The Yangtze River Delta region is the area in China where enterprises that produce micro-motors, supporting components and permanent magnetic materials for motors are most concentrated, and its industrialization supporting capacity is gradually maturing.

At present, with the transfer of the international micro-motor market to China, foreign-funded enterprises remain the main body of the domestic micro-motor industry. For instance, Wanbaozhi Motor Co., Ltd. is the world's largest manufacturer of micro-motors, with an annual production capacity of 2 billion units. Dechang Motor holds a global leading position in the field of micro-motors and drive subsystems, with a daily production capacity of 3 million motors and drives, and an annual production capacity of over 1 billion units, among which automotive micro-motors account for 50%.

In addition, the micro-motor industry in Taiwan, China, has also made considerable progress. The products have evolved from brushed motors to brushless spindle motors, precision stepper motors, precision servo motors, etc. The manufacturing equipment and testing instruments for producing micro-motors in Taiwan are also at a relatively high level.

The technology is at the low end.

Judging from the current development trend of the industry, it has market competitiveness in terms of industrial support and comprehensive production capacity, but there is still a considerable gap in technological level compared with industrialized developed countries.

Experts say that there are many manufacturers of micro-motors in our country, most of which are small and medium-sized enterprises. They cannot form economies of scale, and their products lack technological content and have weak competitiveness. The quality of the products varies greatly. Overall, the vast majority of enterprises are still at a relatively low level in terms of production scale, product research and development, etc.